How to Prepare Your Fresh Produce Supply Chain for Avocado Season

Avocado season is a high-stakes, high-opportunity period for growers, packers, exporters and retailers across the fresh produce supply chain. When Sheppard avocados come into season around February and Hass follow from about May in Australia, every weak link in the chain gets exposed: temperature issues, poor handling, delays in transit, and inconsistent ripening all show up as internal browning, bruising, and disappointed customers.

For exporters and importers using international air freight, those risks are magnified. Avocados are high-value, fast-moving and unforgiving of mistakes, but with the right preparation, they can also be one of the most rewarding categories to move.

Your Roadmap to Proactive Preparation

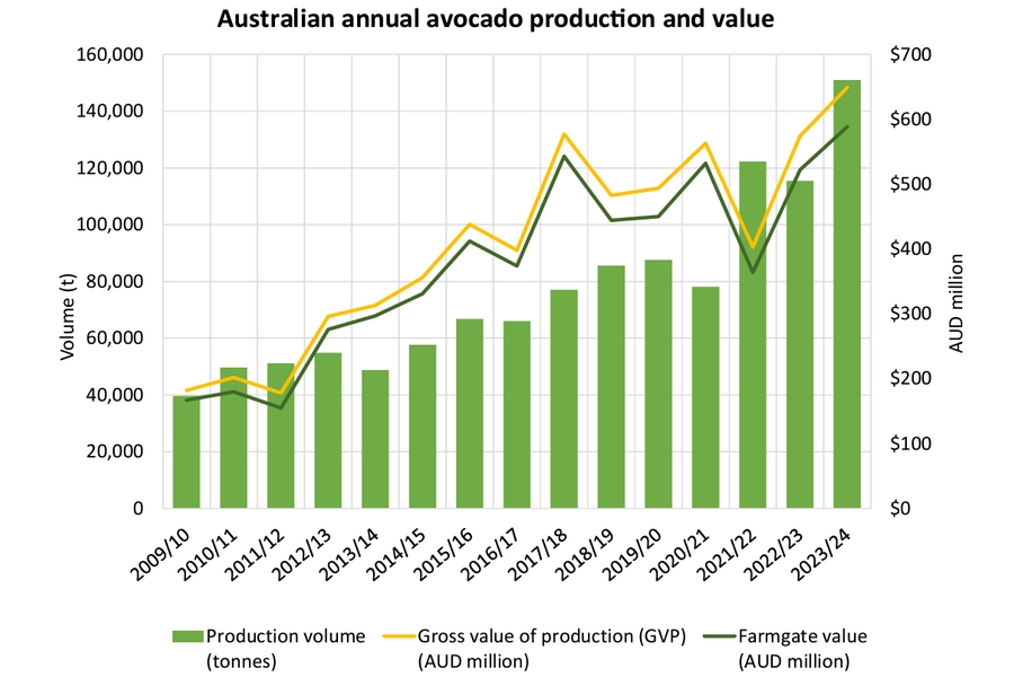

Source: Avocados Australia

This guide walks through how to get your fresh produce supply chain avocado-ready well before peak season hits, with a focus on:

- Understanding avocado seasonality and fruit behaviour

- Building a resilient quality system

- Optimising transport, inventory and ripening

- Managing risk and food safety from the orchard to the overseas market

- Leveraging technology and data for smarter planning

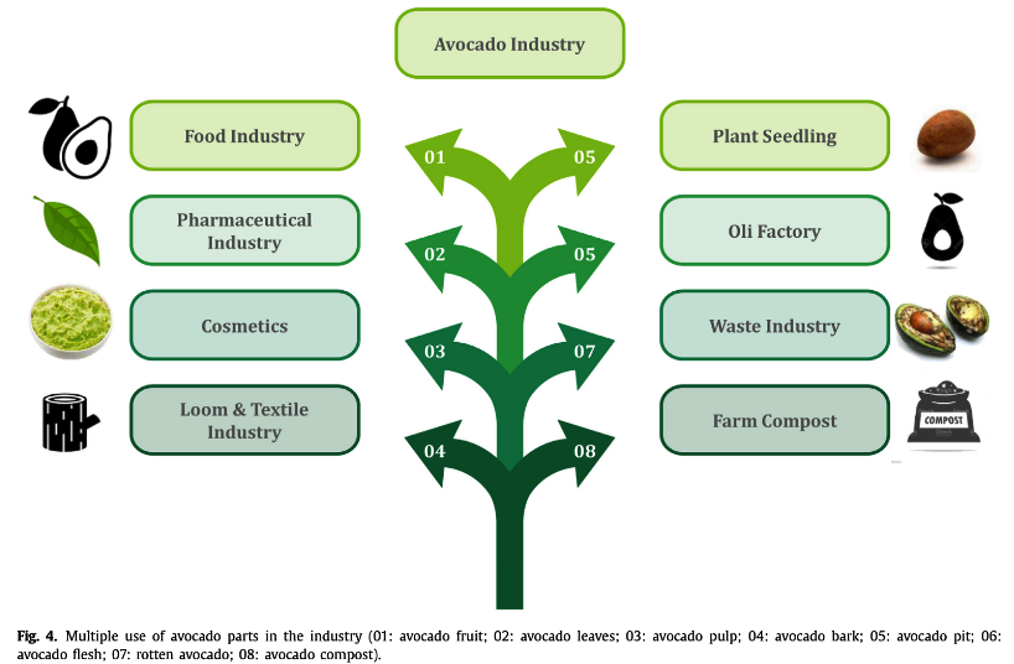

Source: Avocados Australia

A facility should offer:

- Reefer plug points so containers remain powered and stable on-site

- Purpose-built loading docks that reduce manual handling and impact points.

- Pallet handling procedures that prioritise placement, not throwing or dropping cartons.

- Clear SOPs for receival checks (pulp temperature, DM certificates, visible damage) to identify issues early.

- Quality management plans that align with industry best practice resources and customer specs.

At Vision International, goods are cleared at our facilities before arriving at port, as we are an approved quarantine facility.

How do you optimise logistics and inventory?

During peak avocado season, air freight and cool-chain capacity tightens, especially when avocados overlap with other high-value perishables. Strategic planning should include:

- Forward-booking air freight capacity into key markets ahead of Sheppard and Hass peaks.

- Matching flight schedules to ripening windows; for example, shipping firm-ripe or sprung fruit timed to arrive at destination DCs in the ideal ripeness band.

- Building contingency routes (alternate carriers or hubs) in case of weather disruptions or capacity squeezes.

When your logistics partner is also accompanied by a Department of Agriculture Authorised officer on-site, you reduce hand-offs, shorten delay times, and keep fruit under temperature control through inspections and clearance.

Real-Time Monitoring and Sensor Technology

Modern avocado supply chains increasingly rely on IoT sensors and data loggers to keep the invisible visible:

- Shock and impact sensors that record drops or severe handling events at the pallet or carton level.

- Alerts when conditions move outside the agreed spec, allowing proactive interventions before quality is lost.

When this data is integrated directly into your logistics provider’s systems, exceptions can trigger automatic workflows: quarantine holds, QC inspections, or reprioritisation of affected stock.

How Does Vision International Help?

We support you with perishables; it's a niche business and requires specialist knowledge to get it right. If you are exporting or importing perishables (avocados, or any other type of fruit or vegetable), you need a logistics partner that has the best equipment, training, and experience to ensure your product gets to where it needs to go without spoiling.

From pharmaceuticals to fresh produce and everything in between, our home-grown expertise gives you confidence that your cargo is in safe hands. Get in touch with us today to get things moving. What can you expect from us?

• A highly experienced and knowledgeable team managing your freight

• Operations running 7 days a week, 365 days a year

• A dedicated customer service team ready to support your needs

• DAFF-approved, quarantine-compliant facilities

• Expert handling of both international and domestic perishable freight

• Permanent space allocations on key premium air routes

• Access to a global network of specialist perishable logistics forwarders

• In-house quality inspections conducted on arrival

• ISO 9001 accredited, Australian Trusted Trader status, and HACCP certification

Learn more: Exporting Australian Produce By Air: Best Practices for Compliance and Shelf Life.

During peak avocado export windows, access to confirmed space on premium carriers such as Singapore Airlines (SQ), Cathay Pacific (CX) and Malaysia Airlines (MH) plays an important role in protecting transit times, temperature control and on-time arrival.

Established freight forwarder relationships (which Vision International provide) can help exporters secure allocation when uplift capacity tightens.

Perishable Freight Forwarding Support: Contact Us

With the right planning (and the right partners in perishables and international air freight) you can expect excellent quality and repeat orders from happy customers.

Founded in 1995, Vision International Logistics is a fully Australian-owned provider of transport and logistics solutions.

From day one, we’ve specialised in niche areas of forwarding (particularly time-critical and temperature-sensitive cargo_ supported by a highly skilled team and dedicated project logistics specialists.

With our head office in Brisbane, we understand the Australian landscape better than anyone. Over the years, we’ve expanded into a full-service logistics provider, helping businesses navigate complex global supply chain partners with confidence and ease.

Whether you need support with international freight forwarding, sea freight, air freight, customs, or project cargo, Vision International Logistics can efficiently manage and transport cargo across the world.

Call +61 7 3866 7900 or email enquiries@vision.com.au and we'll be happy to support your logistics planning.

Find out more about our values and our accreditation.